SUS (stainless steel) material test piece/specimen

This page introduces test pieces and specimens made of SUS (various types of stainless steel) materials that can be manufactured at TDC.

Contents

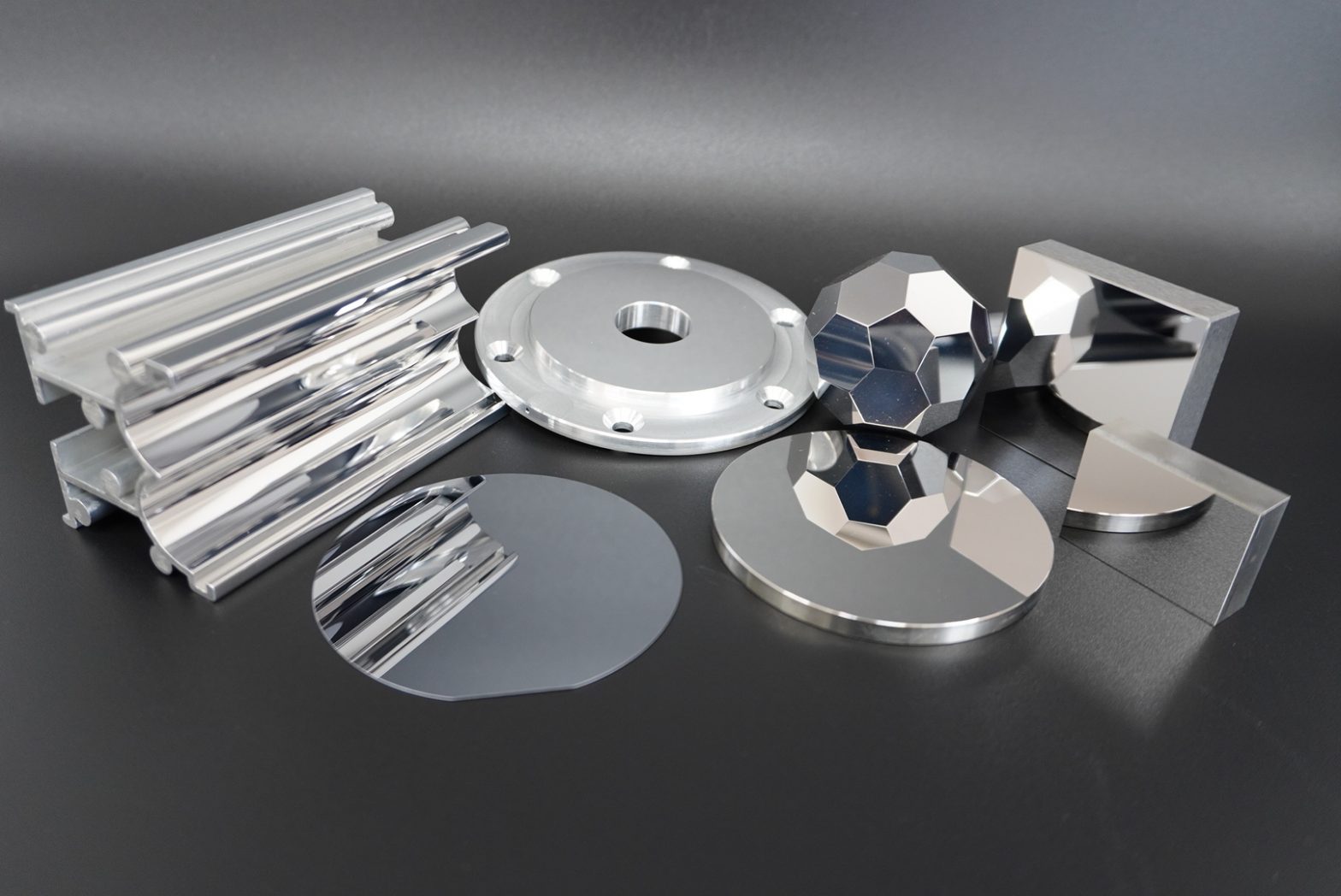

TDC’s SUS material test piece/specimen

At TDC, we accept orders from manufacturing to processing of test pieces and specimens using various SUS (stainless steel) materials.

In production, it is possible to respond from cutting processing. With our special polishing and grinding technology, we are able to produce a variety of test pieces, from mirror surfaces with a surface roughness of Ra1nm to pear-skin (frosted glass).

Examples of SUS materials that can be used to manufacture and process test pieces and specimens

Below are some examples of SUS materials that we receive requests for.

| Material | Feature |

| SUS301 | A material with less nickel and chromium than SUS304 and a higher carbon content. The material strength is high, and the strength is higher than other stainless steel materials. |

| SUS303 | It has the characteristics of being easy to shave and easy to machine because the chips are clean. |

| SUS304 | Compared to other stainless steels, it has excellent cold workability and weldability, making it easy to bend and weld. |

| SUS310 | Among stainless steels, it has excellent acid resistance and is often used as a heat-resistant steel. |

| SUS316 | It has excellent corrosion resistance in various media and is also suitable for marine environments. |

| SUS321 | Stainless steel based on SUS304 with titanium added to improve the corrosion resistance of welds. It is also characterized by high temperature strength. |

| SUS403 | It has excellent corrosion resistance and toughness after heat treatment, and can be hardened by quenching and tempering. Suitable for applications that require heat resistance and high strength. |

| SUS410 | Stainless steel with corrosion resistance after heat treatment and high machinability. Corrosion resistance is inferior to other stainless steel materials, but hardness can be strengthened by quenching. |

| SUS420J2 | One of the characteristics is that it has a high carbon content and has properties that are very close to those of iron. Although it has the disadvantage of being prone to rusting, high strength and high hardness can be obtained by heat treatment such as quenching and tempering. |

with nano-level precision polishing.

and production from single units to mass production.

Please also refer to the “Polishing of stainless steel” page for the stainless steel polishing performed by TDC.

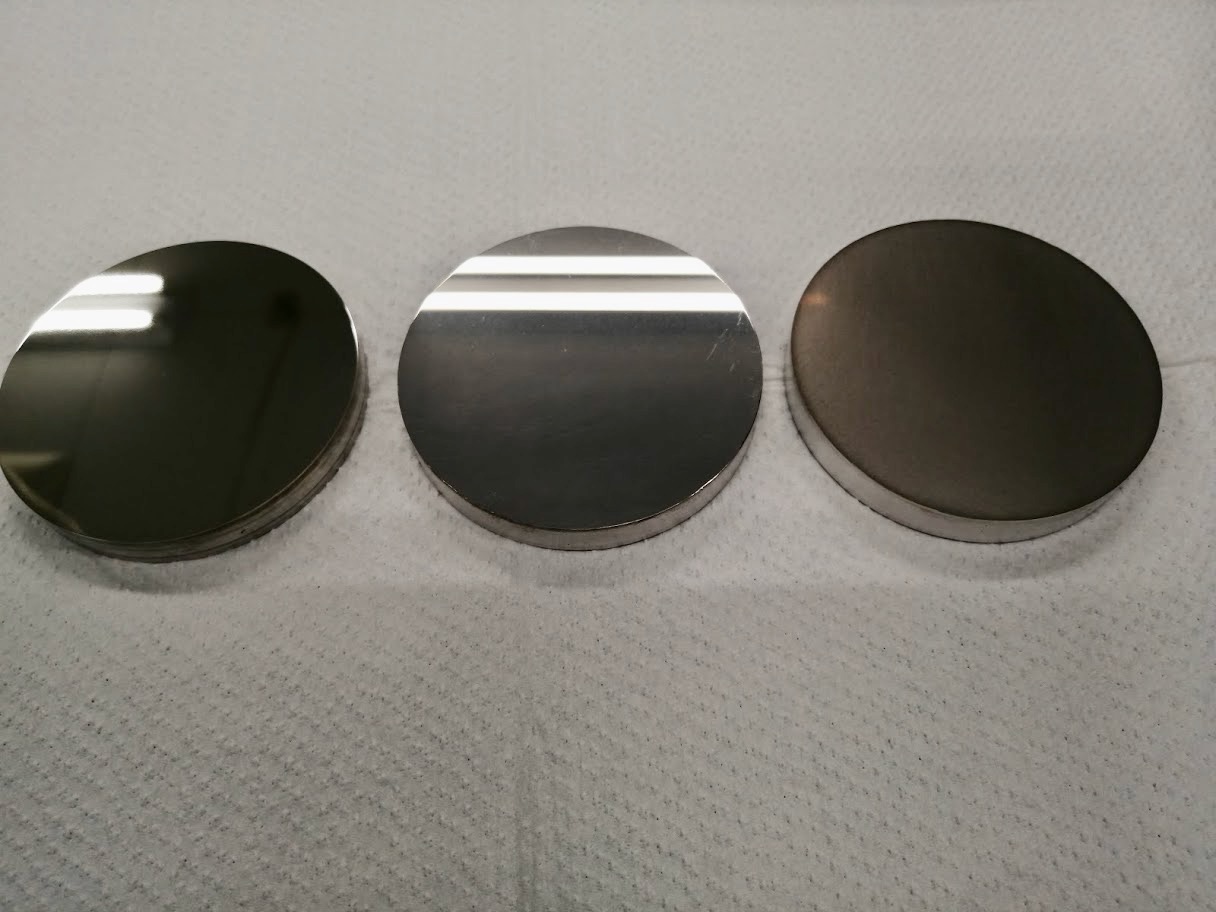

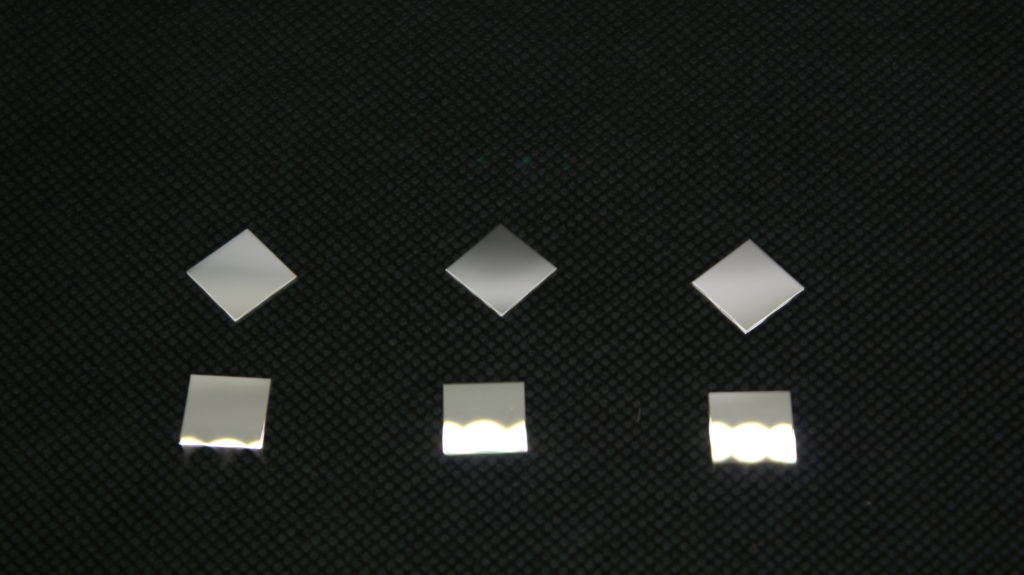

Product example of TDC’s SUS test piece

Some of the SUS test pieces manufactured at TDC are also available on Amazon.

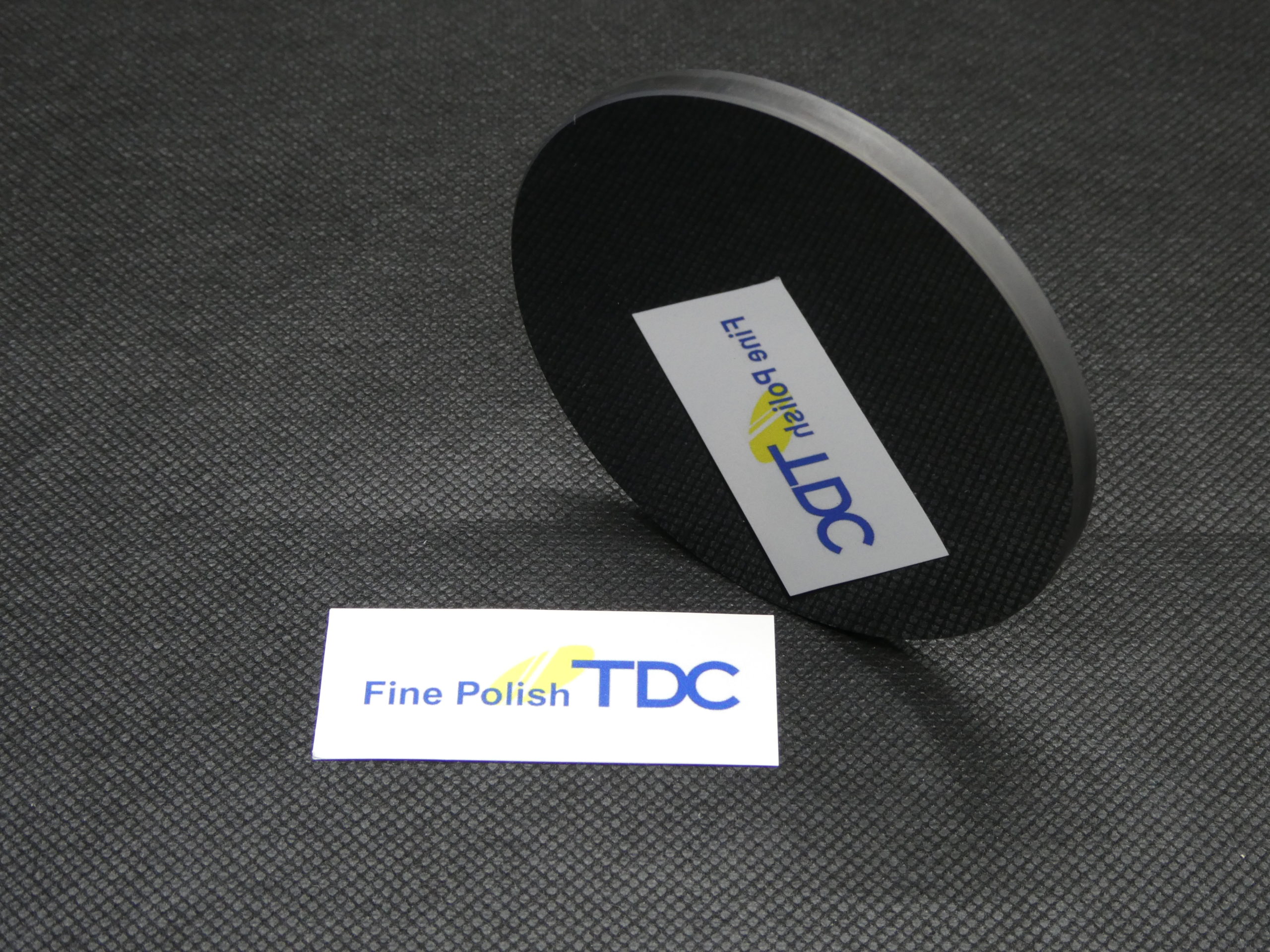

This is a test piece/specimen with one side finished to a mirror surface of Ra1nm or less by TDC’s specialty lapping process.

We also enclose surface roughness data measured with a non-contact type measuring machine

SUS304

| Item Name | testpiece SUS304 |

| Material | SUS304 |

| Roughness | Ra<1nm(Surface roughness data enclosed) |

| Size |

|

| Quantity | 1、5、10、20 |

| Feature |

|

SUS316

| Item Name | testpieceSUS316 |

| Material | SUS316 |

| Roughness | Ra<1nm (Surface roughness data enclosed) |

| Size |

|

| Quantity | 5、10、20 |

| Feature |

|

Related page

- What is a chuck table? | Basic information and description of types, Processing accuracy at TDC

- Copper polishing

- Precision processing of crystal materials and glasses

- Polishing after thermal spraying

- Mirror Finishing/Mirror Polishing

- Sapphire polishing

- Polishing of plastic/acrylic resin

- Polishing after surface treatment/coating

- Precision parts processing

- KEYENCE measuring instruments used at TDC

- Precision Cleaning Service

- Symbol used for polishing

- SUS (stainless steel) material test piece/specimen

- Polishing of SiC

- Polishing of titanium

- Cylindrical grinding/cylindrical polishing

- Mold Processing

- Precision machining of ceramics

- ガラスエポキシ(ガラエポ)の精密加工

- Type of polishing process

- 真鍮の精密加工・研磨加工

- What is the accuracy that can be achieved by polishing?

- Principle of polishing process

- Semiconductor Wafer Cleaning

- Ultrapure Water Cleaning

- Bruker “Dimension Icon”

- Talysurf

- Talyrond

- Dial gauge

- Precision processing of resin and plastic

- Polishing process for Resin

- Precision Measurement

- Mirror-finishing for aluminum

- Mirror-finishing for plastic/acrylic resin

- Wafer Cleaning Equipment

- Mirror Polishing for Stainless Steel/SUS304

- Metal polishing process

- Mitutoyo measuring instrument used in TDC

- Polishing of Aluminum

- Optical Nano Gauge

- TDC’s precision machining

- 微細加工とは? | 基礎知識と加工方法の解説

- What is CMP

- What is polishing?

- About Lapping and Polishing